Hirsch is the only Brother DTG/DTF dealer with nationwide coverage.

Benefits of DTG

Direct to garment printing (DTG) uses inkjet printing technology to send full color designs directly from a computer to a digital printer with a garment loaded into it. With minimal training or experience, you can use our DTG printers to create high-quality printed garments at production level speeds. Say goodbye to labor intensive processes and say hello to technology: faster output; easy customization; flexible quantities; and expanded product offerings.

GTXpro – Most Advanced Model for Start-Ups and Medium-Sized Print Shops

GTXpro – Most Advanced Model for Start-Ups and Medium-Sized Print ShopsDesigned to be even easier to operate, to provide even faster production level print speed, and to be even more efficient, the new GTXpro direct to garment printer is the latest product of Brother’s long history of DTG innovation. It all comes with Brother’s At Your Side Commitment, which includes a strong warranty, technical support and on-site installation.1

GTXpro B – Special Features for Large-Volume Print Shops

Engineered specifically for high-volume print shops that run multiple shifts, the GTXpro B features an intelligent ink system that keeps large volumes of ink in a constant state of readiness. Take advantage of efficiencies in ink systems, maintenance components and operation costs to maximize your ROI. The GTXpro B also gives you the flexibility to scale up in short order to meet the demands of your growing business, but not before you have the volume to justify it.

GTX600 - Industrial Mass Production DTG Printer

Built for industrial-level DTG printing, GTX600 is designed to be able to operate 24/7 with minimal downtime. Featuring a built-in humidifier, intelligent platen height system, and operator-friendly features, GTX600 empowers greater efficiency, productivity, and automation for your DTG printing operation. Now available in standard or extra colors models, which includes additional green and orange ink options for an even greater color gamut.

Digital Line - Single Operator, Total DTG Solution

This system allows for a totally integrated process - pretreats, cures, heat presses, prints, and finishes - with a single scan and loading of the platen by one operator. From there, each step is automated and tailored to the specs of that specific garment. This automation saves time, labor, and helps eliminate opportunities for human error. Whether a one-off item or a high-volume order, Digital Line 2000 helps you print more in less time and with fewer operators.

Discover the advantages that Brother DTG/DTF machines deliver.

PRE-TREAT

Pretreating by hand is out, these machines will speed up your production.

CURE

Water-based digital inks require airflow as well as consistent heat. Learn about the different models here.

Brother GTXpro B introduction

What's new with Brother DTG

GTXpro B features explained

Hirsch can help you with that.

Hirsch has the most knowledgeable staff in the country when it comes to DTG equipment and applications. Our distribution center and Solution Studio are both located in NC. Our partnership with Brother allows us to stock, install, and service every piece of equipment with in-house technicians. We offer world-class support and fast, easy delivery to all of our valued customers.

Talk with a Specialist

Enter your info below to be contacted.

Hirsch offers only the best for your business | View Products

SPECIALTY

Awesome Features!

Special models

LEATHER

CHENILLE

HEATER WIRE

SEED BEAD

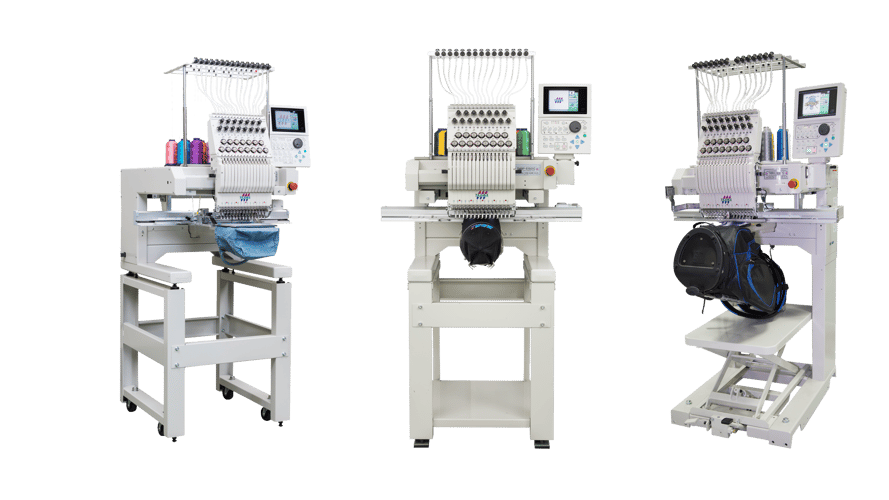

SINGLE HEAD

Awesome Results!

6 Big Models

TMBU

TMBP

TMBR

TMEZ

ACCESSORIES

Awesome Add-ons!

tools of the trade

HOOPS

ATTACHMENTS

HOOP MASTER

SMAKE