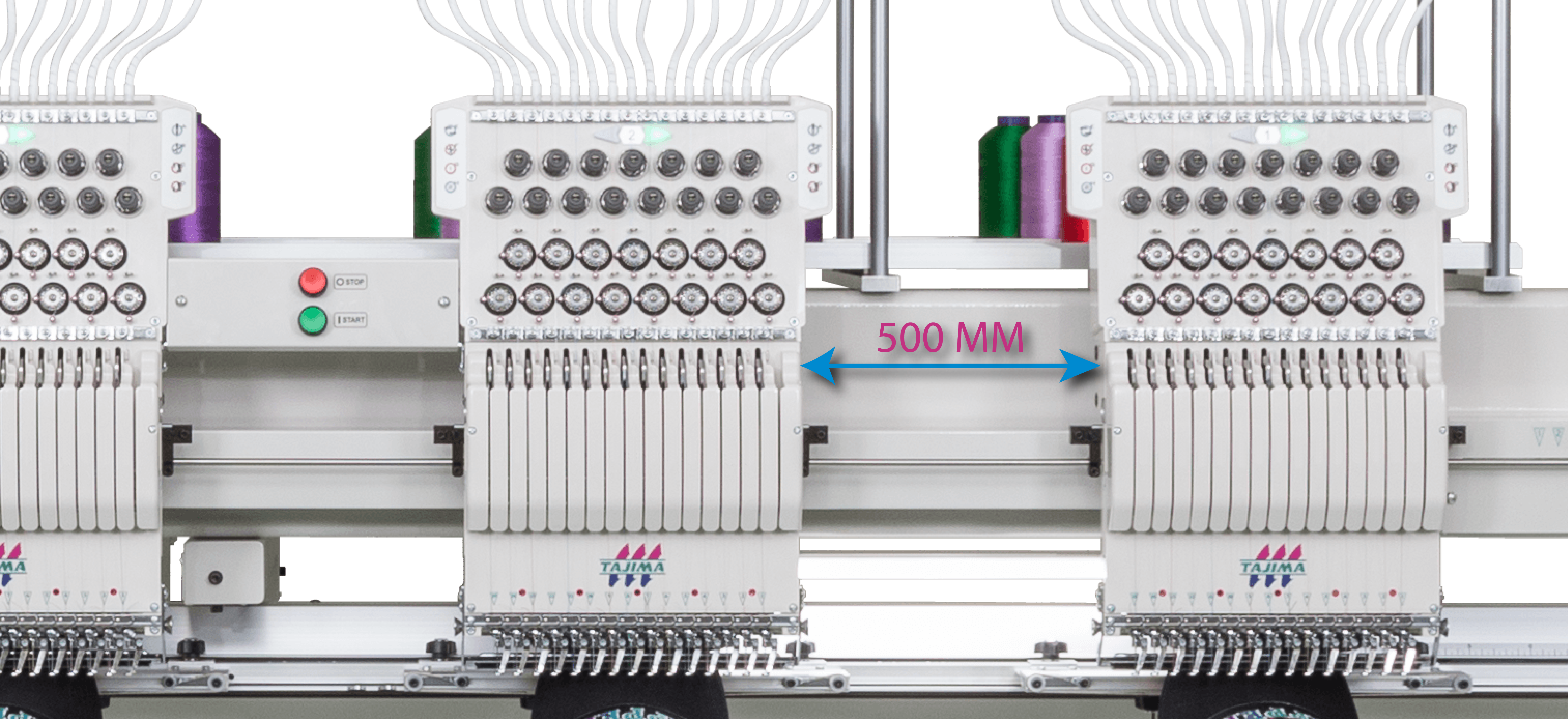

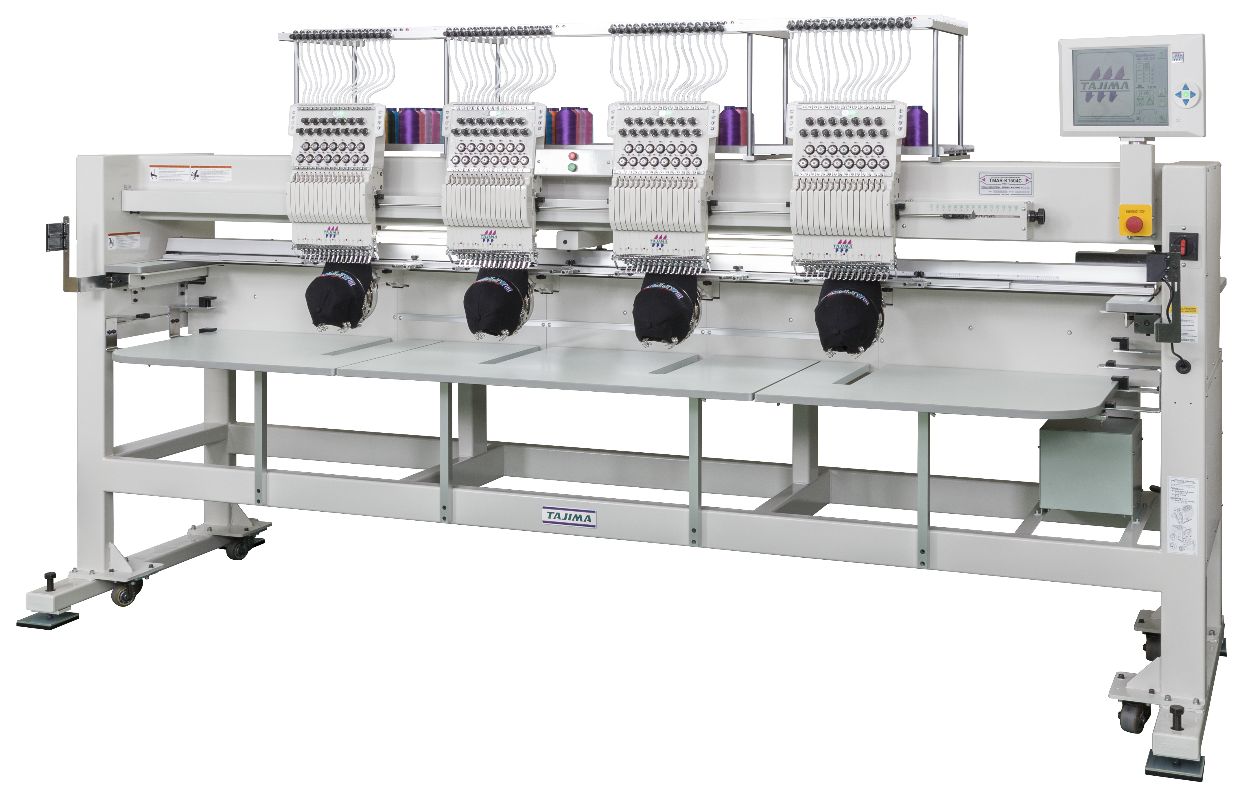

TMAR-KC Series

Interested in TMARK?

Let us be your guide, fill out the form below to have your local sales expert reach out to answer all your questions.

The Future of Embroidery

The ultimate model was born from the Tajima technology evolution. The Tajima Cylinder Arm Type TMAR-KC Series is born. The embodiment of Tajima's technologies with high production efficiency, ultimate quality, overwhelming durability, and performance.

Technology for Elaborate Embroidery Detail

A newly developed digitally-controlled presser foot that can adjust its bottom dead center and each stroke for each needle bar (color change) has been specifically designed for the TMAR-KC Series. Quickly and electronically control the height of the presser foot to provide the precise presser foot height for specific materials. Great for delicate materials such as silk or leather and significantly improves the production of 3D Puffy Foam.

Easy Maintenance

By introducing the crank drive, a new driving system, into the embroidery machine head, overwhelming durability has been realized. Also, maintenance has become simpler, and the lubricating frequency has been reduced to one-twentieth (once in 6 months)

Touch-Operation Display

This display is equipped with an intuitive, easy-to-use operation panel with easily identifiable icons and a high-capacity memory that can store up to 40 million stitches or 650 designs

KEY FEATURES

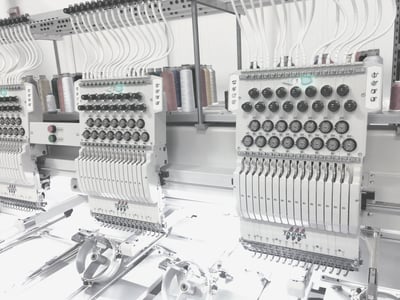

Direct Head Controls

Various operation switches are located on the each head. Since all of the main functions of the operation panel can be manipulated in front of each head, the working efficiency of operators has been improved.

Touch Screen Panel

12.1-inch TFT touch panel

The large monitor allows intuitive operation of the panel.

DCP

Digitally controlled presser food can be adjusted for each needle according to the product thickness. When the needle moves up the presser foot lags behind to reduce fabric flutter.

MULTI-HEAD STANDARD FEATURES

-

Auto Color Change

As design dictates the needle bar will automatically change based on the needle assigned

-

Auto Thread Trim

Trimmer exists within the needle plate to trim where needed within a design and at color changes.

-

Barcode Ready

Multiple USB ports allow for open space for a barcode reader to be used when networking allows.

-

High Speed Rotary Hook

Hook rotates around bobbin to accommodate for the higher speed capabilities of the machine.

-

Quick Changeover

Thumb screws are in place to allow for easy change over from tubular to cap as well as moving to a larger field.

-

Spiral Tubes

Plastic spiral tubes allow thread to keep separated to alleviate knotting or twisting.

-

Lan Enabled

Each machine is ready for network connection with Tajima DG16 by Pulse software.

Tajima - TMAR-KC Type 2 from HirschSolutions on Vimeo.

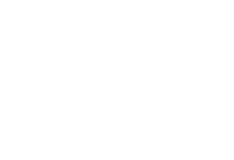

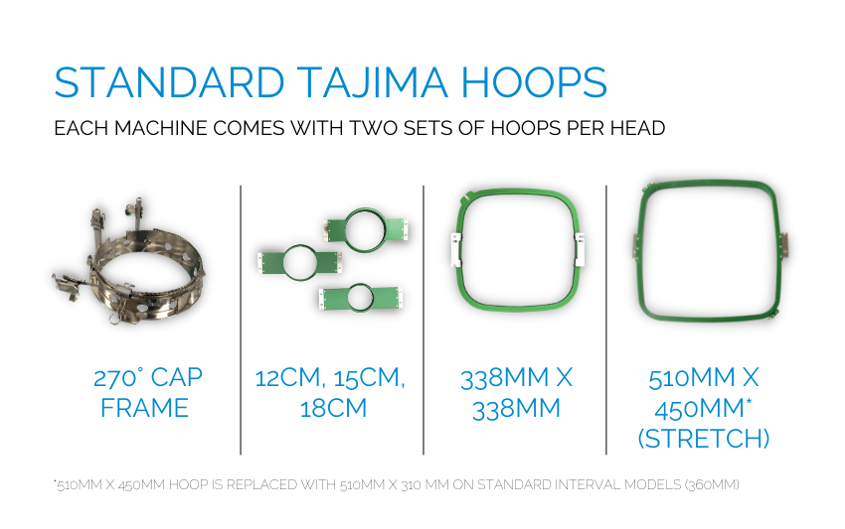

Head interval refers to the space from one head to the next. Standard machines refer to machines with 360mm (14") head intervals.

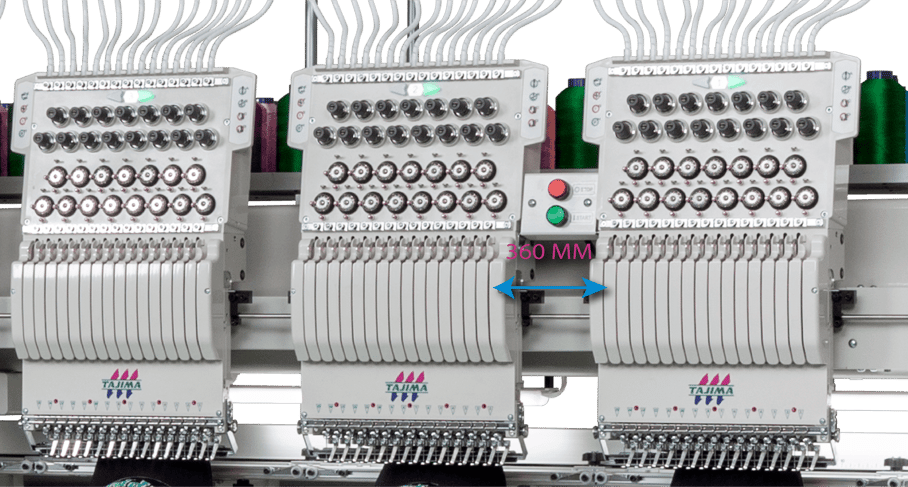

Stretch machines have a 500mm (19.6") head interval. A larger interval makes is easier for larger, bulky products to fit comfortably between heads and a larger x-axis embroidery field.

Standard vs Stretch

360 MM Head Interval

The standard 360 MM head interval machines are ideal for producing a standard mix of products that are not limited to caps, shirts, sweatshirts, jacket backs, and infinitely more.

Standard vs Stretch

500 MM Head Interval

The 500mm head interval provides more space between heads which makes it easier to accommodate larger, bulky products such as sweatshirts, jackets, blankets, etc.. This setup is ideal for customers who do a larger percentage of these types of items and can accommodate the larger machine size.

Safety Beam Sensor

A beam surrounds the work area while machine is in motion. If the plane is broken the machine will immediately stop.

Thread Locking System

The thread locking system secures the thread after a trim to prevent the thread pulling out during start.

LED Needle Base Light

LED needle base light illuminates the needle area and enables the operator a better view of the item being embroidered.

Trimmed Needle Plate

A shorter needle plate offers an increased embroidery area on many items such as small sleeves or caps.

Slim Cylinder

The slim cylinder makes it possible to embroider on smaller objects such as socks, gloves, and pockets.

Versatile Cap Driver

The new cap driver incorporates a lower shaft and a third locking pin to stabilize the cap while running to enhance quality, and run at higher speeds.

Steep Head Tilt

The steeper head angles the bill of any cap and allows for placement closer to the brim increasing the embroidery area.

Thread Break Detection

A sensor monitors the thread movement while stitching. If the tension on the upper or lower thread is broken the machine stops stitching relaying an error on the controller.

MODEL CONFIGURATIONS

| No. of Heads | Head Interval | Cap | Tubular | Dimension |

|---|---|---|---|---|

2 |

500mm |

3" x 14.2" |

17.3" x 16.5" |

89"W x 54"D x 69" H |

4 |

500mm |

3" x 14.2" |

17.3" x 16.5" |

129"W x 54"D x 69"H |

6 |

360mm/500mm |

3" x 14.2" |

17.3" x 11"/17.3" x 16.5" |

130"W x 54" D x 69" H/168"W x 54" D x69" H |

8 |

360mm/500mm |

3" x 14.2" |

17.3" x 11"/ 17.3"x 16.5" |

158"W x 54" D x 69" H/207"W x 54"D x 69"H |

.jpg?width=400&height=113&name=Hirsch-(400).jpg)