Control costs, add flexibility, and give your customers a wow factor.

Get a quote

Interested in learning more about Seit SL-10 bridge laser as the next add on to your embroidery department? Let us know and one of our sales reps will reach out!

Add a headline.

Lorem ipsum dolor amet food truck affogato cronut freegan skateboard photo booth, tousled pickled 90's wayfarers retro succulents hoodie edison bulb ramps. XOXO seitan tote bag, offal vape air plant disrupt chia plaid taxidermy cloud bread microdosing 8-bit.

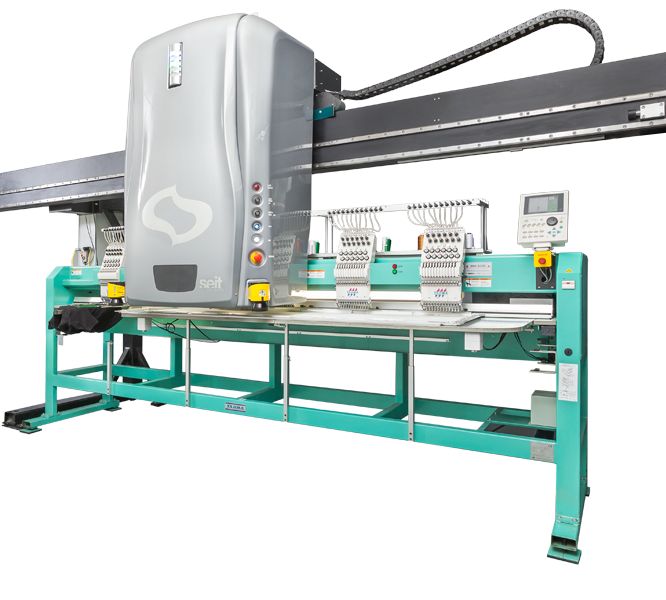

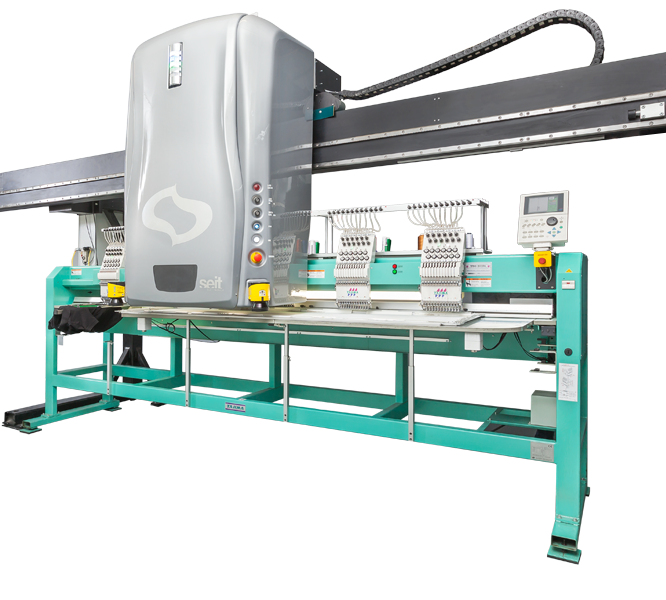

Seit SL-10 Laser Bridge

SL-10 is the result of more than 20 years of experience and new functionalities of laser systems for the embroidery field. Merging together all the improvements and suggestions from the market has made SL-10 the best high-tech product to express your creativity without compromise.

Major features set Seit SL-10 Laser Bridge apart from all the rest.

-

CO2 Textile Laser engineered for maximum output and reliability

-

Galvanometric scan head

-

Custom length beam to incorporate any setup installed on C shaped supports for maximum strength and minimal space

-

Optional field size (300mm x 300 mm or 500mm x 500 mm)

-

The water-cooling system cuts down cooling to increase production time

-

Professionally installed and calibrated on-site by a Hirsch technician

Hat Kits

The only solution on the market that allows applications to be cut directly on closed caps using a surface of 140 °. Available for Tajima machines only.

Apparal Textiles

Provide your customers with an array of options to to add interest to your traditional embroidery. With applique and reverse applique processes cut down on time and resources by adding Seit laser technology to your business.

Call to Action

Get a quote

Interested in learning more about Seit SL-10 bridge laser as the next add on to your embroidery department? Let us know and one of our sales reps will reach out!

Add a headline.

Lorem ipsum dolor amet food truck affogato cronut freegan skateboard photo booth, tousled pickled 90's wayfarers retro succulents hoodie edison bulb ramps. XOXO seitan tote bag, offal vape air plant disrupt chia plaid taxidermy cloud bread microdosing 8-bit.

The Performa series brings the powerful features and functionality of the Bridge Laser in a stand alone unit. With the compact size and traditional power requirements, the Performa brings laser technology to those who never thought it was possible.

Using the SEIT Textile Laser Technology, you can easily combine interesting fabrics and creative cut-outs to produce large-scale designs that can't be replicated by the other shops. The end-result is one-of-kind products, which means higher profits and less competition.

Reverse applique can't be easily reproduced by any other decoration method, so its unique to the SEIT Textile Laser System.

The Seit Performa 500 technology allows the embellishment of products beyond textiles.

Adjustable laser strength for a variety of substrates

-

-

Multiple Cutting areas

-

Galvanometric scan head

-

Custom length beam to incorporate any setup installed on C shaped supports for maximum strength and minimal space

-

Optional field size (300mm x 300 mm or 500mm x 500 mm)

-

The water-cooling system cuts down cooling to increase production time

-

Professionally installed and calibrated on-site by a Hirsch technician

-

Want to know more?

Interested in learning more about Seit SHL option as the next add on to your embroidery department? Let us know and one of our sales reps will reach out!

Add a headline.

Lorem ipsum dolor amet food truck affogato cronut freegan skateboard photo booth, tousled pickled 90's wayfarers retro succulents hoodie edison bulb ramps. XOXO seitan tote bag, offal vape air plant disrupt chia plaid taxidermy cloud bread microdosing 8-bit.

Expand your embroidery programs with the SHL5. Now five times faster than its predecessor, the SHL5 will reduce stitches times, broaden creative range, while increasing profitability. Doing complex segmented appliqué designs with limitless material choices will have the most impact on your program for the greatest opportunity of success in your business TODAY.

Higher Profit in Less Time

Single Head Laser applications have a higher perceived value, easily increasing profitability. Similar embroidery stitch count designs can be created using appliqué for greater impact and marketability. Less time is required to stitch them, increasing production output. Single head production has never been more profitable than now in doing the current and trendy fashions or corporate appliqué work.

Eliminate Ordering of Pre-Cut Letters and Appliqués

In today's world of immediate turnaround, it has never been more important to respond quickly in order to increase business. Creating art and letters to be cut in a separate operation, or ordered by an outside source, is eliminated as is maintaining expensive inventories.

Decrease Processing Time

Eliminating separate design processes for appliqué and fonts saves considerable time while minimizing the technical requirements. Adhesives are no longer required, saving time, money and the environment. No more outline stitches referencing placement.

Simple to Setup

What makes the SHL5 an outstanding choice for your program expansion is the easy learning curve. There is no complicated software to learn. Simple to follow instructions for converting a stitch line to a cut line makes the process fast and easy. With the laser positioned directly in front of needle one, all segments assigned to it will be converted from stitch to laser cut.

Creatively Driven

Complex and segmented appliqués are easy to cut and almost any soft and lightweight material can be considered, opening the door to greater designs in spirit wear and corporate logos. With cutting done after the tack down, rigid materials are no longer a necessity. Creating multimedia products by combining print and laser appliqués is one of the surest way to lead in the marketplace. You are only limited by your own creativity for today's trends in distressed, reverse and multi-layer appliqués.

.jpg?width=400&height=113&name=Hirsch-(400).jpg)

-1-1.png?width=407&height=500&name=Seit_Performa%20500%20(4x4@300dpi)-1-1.png)