Reliable, High-Performance Dryers from Brown Digital

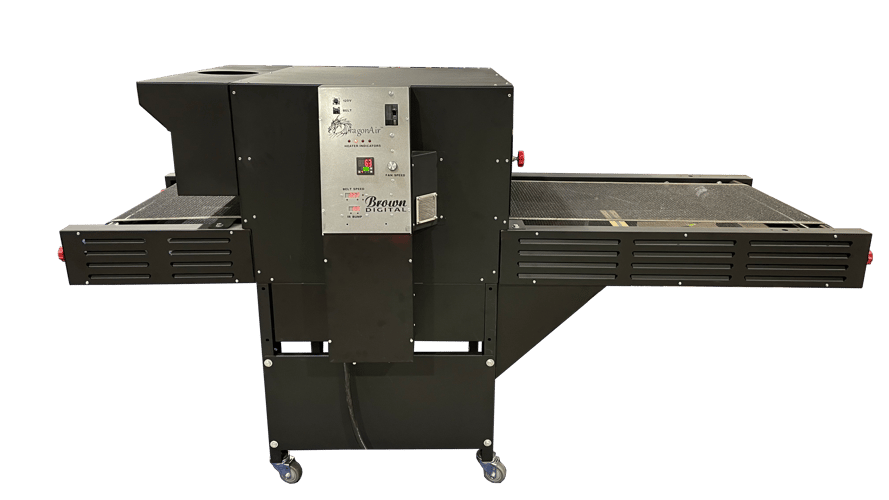

DragonAir Knight

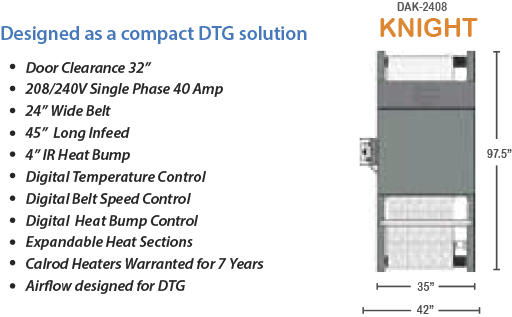

DAK-2408

DragonAir Fire

DAF-3611

FireFly

Curing System

Synergy

Pretreat

DAK-2406X was designed with DTG printers in mind. This compact dryer offers a small footprint with all the benefits of a full-size conveyor belt dryer.

DragonAir Knight can quickly and easily change temperature allowing for a better array of garments at a print-on-demand speed. The quick temperature change also allows for better dye migration control for top of the line quality assurance on all fabric types.

The infrared bump allows for a quick blast of heat acting as a flash to hasten curing time as well as completely eliminating unsightly pretreat boxes.

Infrared Bump

4" Blast of heat for quick cure time

Infrared Bump

4" Blast of heat for quick cure time

Infrared Bump

4" Blast of heat for quick cure time

-

Recommended Settings

-

Features

- 36" wide belt

- 8" IR Heat Bump

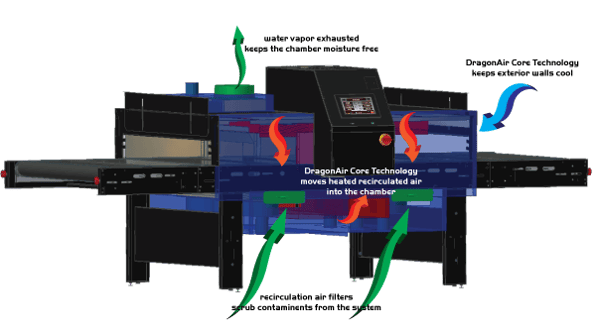

- DragonAir CoreTechnology

- Touchscreen TRX control software

- Variable convection air flow & vapor exhaust

- Adjustable Heater Rack

- Independent baffle height adjustment

- single phase or three phase power

- Belt Speed adjust from 1 sec to 99 min

- Calrod Heaters warranted for 7 yrs

-

Documents

-

Videos

Infrared Bump

8" Blast of heat for quick cure time

Air Flow

Adjustable convection controls for DTG

Touch Screen Controls

Easy to create and save programs

The Synergy industrial pretreat machine provides complete multi-variate control of each garment. The system is designed for high volume digital printers and connects directly to the FireFly curing system, allowing for rapid evacuation of pretreat solution and delivery to the DTG printer..

The Synergy industrial pretreat machine provides complete multi-variate control of each garment. The system is designed for high volume digital printers and connects directly to the FireFly curing system, allowing for rapid evacuation of pretreat solution and delivery to the DTG printer..

Configured to spray two different pretreat solutions, and with the Central Source, to mix the solutions from concentrated form, the Synergy system is a large scale solution to a production bottle neck. Simple to operate and easy to clean, this unit features software scheduled maintenance of the nozzle and valves with built in flow sensors.

The transport belt is an integral part of the system. This allows for the movement of the garment from the Synergy system directly into the FireFly curing oven. One continual flow that is monitored together by the Linx software integration tool.

SYNERGY FEATURES

- Synergy Linx controls module

- Single operator

- Single nozzle for consistent coverage

- Quick attach nozzles

- Adjustable Spray area 3" -24"

- Multiple spray zones

- 2 pretreat solutions through 2 sets of nozzles

- Flow sensors

- Auto transport to FireFly cure

- Manual and queue modes

- Projection visual verification system

- Auto maintenance procedures

- Full system water flush

- Automatic maintenance procedures

- Touchscreen and scanner controlled

.jpg?width=400&height=113&name=Hirsch-(400).jpg)